Pawar Industries is leading Manufacturers in Pressure Regulating Valves

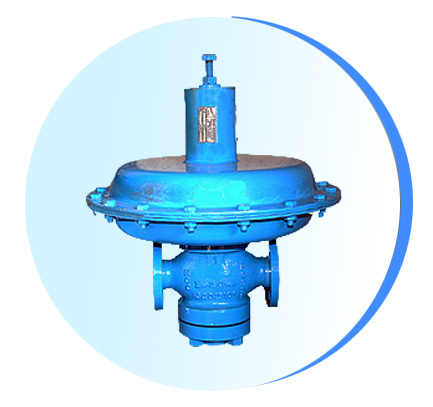

are crucial components used in industrial applications to regulate and control fluid or gas pressure. These valves play a vital role in maintaining optimal pressure levels, ensuring system efficiency, and protecting equipment from damage. In this comprehensive guide, we will delve into the working principles, advantages, applications, and maintenance considerations of Pressure Regulating Valves. Whether you are an engineer, technician, or someone interested in pressure management systems, this article will provide valuable insights into the functionality and benefits of Pressure Regulating Valves.

Working Principles of Pressure Regulating Valves -

Pressure Regulating Valves operate based on the principle of automatically adjusting the flow rate to maintain a consistent downstream pressure, regardless of changes in upstream pressure. These valves consist of a valve body, diaphragm or piston assembly, spring, and control mechanism.

When the upstream pressure exceeds the desired setpoint, the diaphragm or piston senses the increase and pushes against the spring, closing the valve and reducing the flow rate. This process continues until the desired downstream pressure is reached. Conversely, when the downstream pressure drops below the setpoint, the diaphragm or piston allows the valve to open, increasing the flow rate to restore the desired pressure.

Pressure Regulating Valves offer precise control and accurate pressure regulation, ensuring stability and consistency in fluid or gas systems.

Advantages of Pressure Regulating Valves -

Pressure Regulating Valves offer numerous advantages, making them a preferred choice in industrial applications that require precise pressure control. Some key advantages include:

a) Optimal pressure management : Pressure Regulating Valves ensure that the pressure within a system remains within the desired range, preventing overpressure or underpressure conditions. This helps protect equipment, enhance system efficiency, and maintain product quality.

b) Accurate pressure control :These valves provide accurate and stable pressure regulation, allowing for precise control over the pressure setpoint. This is critical in applications where maintaining a specific pressure level is crucial for proper system functioning.

c) Flow rate compensation : Pressure Regulating Valves automatically adjust the flow rate to maintain a constant pressure downstream, even when the upstream pressure fluctuates. They compensate for pressure variations, ensuring consistent performance and preventing pressure-related issues.

d) Increased system safety : By preventing excessive pressure buildup, Pressure Regulating Valves contribute to overall system safety. They protect equipment from damage caused by pressure surges and prevent the risk of system failures or leaks.

e) Versatility and adaptability : Pressure Regulating Valves are available in various configurations and sizes to accommodate different flow rates and pressure ranges. They can be applied to a wide range of industries, including oil and gas, chemical processing, water treatment, HVAC systems, and more.

Applications of Pressure Regulating Valves -

Pressure Regulating Valves find applications in diverse industries where precise pressure control is essential. Some common applications include:

a) Oil and gas industry : Pressure Regulating Valves are widely used in oil and gas production, refining, and distribution systems. They help regulate pressure in pipelines, storage tanks, and other critical components, ensuring safe and efficient operations.

b) Chemical processing : Pressure Regulating Valves play a vital role in chemical plants, where precise pressure control is necessary for various processes, such as reactor vessels, distillation columns, and heat exchangers. They maintain optimal pressure conditions and help ensure product quality and system safety.

c) Water treatment : Pressure Regulating Valves are employed in water treatment plants to regulate pressure in pipelines, tanks, and distribution networks. They help maintain optimal flow rates, prevent water hammer effects, and ensure efficient water distribution.

d) HVAC systems : Pressure Regulating Valvesare utilized in heating, ventilation, and air conditioning (HVAC) systems to maintain optimal pressure levels in ducts and pipelines. They ensure proper airflow, prevent system imbalances, and enhance energy efficiency.

e) Pharmaceutical industry : Pressure Regulating Valves are crucial in pharmaceutical manufacturing processes that require precise pressure control, such as tablet compression, fluid bed drying, and filtration systems. They help maintain process stability, product quality, and regulatory compliance.

f) Power generation : Pressure Regulating Valves play a significant role in power plants, including thermal, nuclear, and renewable energy facilities. They regulate pressure in steam, gas, and cooling water systems, ensuring safe and efficient power generation.

Maintenance Considerations for Pressure Regulating Valves -

Proper maintenance of Pressure Regulating Valves is essential to ensure their optimal performance and longevity. Here are some important maintenance considerations:

a) Regular inspection : Conduct periodic inspections to check for signs of wear, corrosion, or damage to the valve body, diaphragm or piston assembly, seals, and other components. Replace any worn or damaged parts promptly to maintain efficient operation.

b) Calibration : Periodically calibrate Pressure Regulating Valves to ensure they are operating within the desired pressure range. This helps maintain accuracy and reliability in pressure control.

c) Leakage prevention : Check for any leaks around the valve body, connections, and seals. Address any leakage promptly to prevent pressure losses and ensure optimal performance.

d) Actuator maintenance : If the Pressure Regulating Valve is equipped with an actuator, inspect and maintain the actuator components as per the manufacturer's recommendations. This may include checking the condition of seals, lubricating moving parts, and verifying proper actuator response to control signals.

e) Training and documentation : Ensure that personnel responsible for maintaining Pressure Regulating Valves receive proper training on maintenance procedures. Keep detailed records of maintenance activities, including inspection dates, repairs, and replacements, to track the valve's performance history.

| Valve size | 1/2"to 2" (15MM - 50MM) |

| Pressure rating | 150#, 300# |

| End connection | Flanged, Screwed, TC end |

| Material | A216 Gr WCB, A351 CF8 (SS 304), A351 CF3 (SS 304L), A351 CF8M (SS 316), A351 CF3M (SS 316L) and as per special specifications. |