Pawar Industries is leading Manufacturers in Valve

Valves are fundamental components used in various industries to control the flow of fluids and gases within a system. From simple household faucets to complex industrial applications, valves play a crucial role in regulating, directing, and stopping the flow of substances. In this comprehensive guide, we will explore the different types of valves, their working principles, applications, and the significance of valves in fluid control systems. Whether you are an engineer, technician, or someone interested in understanding the functionality of valves, this article will provide valuable insights into these essential components.

Types of Valves -

Valves come in a wide range of types, each designed for specific applications and operating conditions. Some common types of valves include:

a) Globe Valves : Globe valves are characterized by a globe-shaped body and a movable plug or disc that controls the flow through the valve ports. They provide accurate flow control and are commonly used in applications requiring throttling or regulating the flow.

b) Ball Valves : Ball valves use a rotating ball with a bore to control the flow. When the ball is rotated, it aligns with the flow path to allow fluid or gas passage or blocks the flow path to provide shut-off. Ball valves are versatile, offering fast operation, tight sealing, and minimal pressure drop.

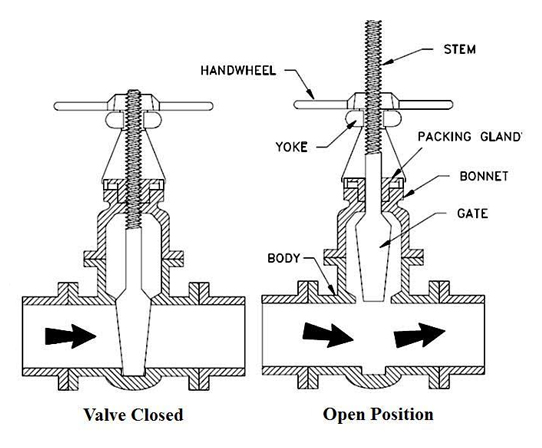

c) Gate Valves : Gate valves feature a gate or wedge-shaped disc that moves perpendicular to the flow path to control the flow. They provide full flow when open and tight shut-off when closed, making them suitable for on/off applications.

d) Butterfly Valves : Butterfly valves use a disc that rotates on a central axis to control the flow. They are lightweight, compact, and cost-effective, making them popular for large-diameter applications and systems requiring quick shut-off.

e) Check Valves : Check valves allow flow in one direction and prevent back flow in the opposite direction. They are commonly used to prevent fluid or gas reversal, ensuring system efficiency and preventing damage.

Working Principles of Valves -

Valves operate based on different working principles depending on their type. However, the fundamental purpose of all valves is to control the flow of fluids or gases. The working principles can be summarized as follows:

a) Movement-based Valves : Valves such as globe, gate, and butterfly valves operate by moving a disc, plug, or ball to regulate the flow. The movement can be linear or rotary, controlling the flow rate or providing shut-off when needed.

b) Pressure-based Valves : Pressure-based valves, such as check valves, work by using the pressure difference across the valve to open or close. They allow flow when the pressure on one side exceeds the pressure on the other side, and they prevent backflow when the pressure conditions change.

c) Diaphragm-based Valves : Diaphragm valves use a flexible diaphragm to control the flow. When pressure is applied, the diaphragm flexes, allowing flow through the valve ports. Releasing the pressure causes the diaphragm to return to its original position, stopping the flow.

d) Control-based Valves : Control valves, equipped with actuators, use an external signal, such as electric, pneumatic, or hydraulic, to regulate the flow. The actuator moves the valve mechanism to open or close based on the control input, allowing precise flow control.

Applications of Valves -

Valves find extensive applications across various industries where fluid or gas control is critical. Some common applications include:

a) Process Industries : Valves play a vital role in process industries such as oil and gas, chemical processing, pharmaceuticals, and food and beverage. They are used for controlling flow rates, pressure, temperature,and fluid compositions during various manufacturing processes.

b) Water and Wastewater Treatment : Valves are essential in water and wastewater treatment plants for regulating the flow of water, chemicals, and sludge. They ensure efficient treatment processes, water distribution, and wastewater management.

c) HVAC Systems : Valves are employed in heating, ventilation, and air conditioning (HVAC) systems to control the flow of heating or cooling fluids. They help maintain comfortable indoor temperatures and optimize energy efficiency.

d) Power Generation : Valves are critical components in power plants for controlling the flow of steam, condensate, or cooling water. They regulate the flow to ensure efficient power generation and system safety.

e) Oil and Gas Industry : Valves are extensively used in the oil and gas industry for controlling the flow of hydrocarbons, gases, and chemicals. They enable safe and efficient extraction, processing, and transportation of oil and gas.

f) Transportation : Valves are employed in pipelines, tanks, and transportation vehicles to regulate the flow of fluids and gases. They ensure safe and reliable transportation in industries such as petroleum, chemical, and transportation infrastructure.

Significance of Valves in Fluid Control Systems -

The valve stem connects the valve actuator to the valve plug, disc, or ball, transmitting the actuating force and enabling the opening or closing of the valve. It is a slender rod-like component that passes through the valve body and is sealed to prevent leakage. The stem material is selected based on factors such as temperature, pressure, and the nature of the fluid or gas.

Valve Seat -

Valves are of paramount importance in fluid control systems for several reasons:

a) Flow Control : Valves allow precise control over flow rates, pressures, and fluid directions, ensuring optimal process performance, product quality, and system efficiency.

b) Shut-off and Isolation : Valves provide tight shut-off, preventing the flow of fluids or gases when required. This allows for maintenance, repairs, and system isolation, ensuring safety and preventing leaks.

c) Safety and Environmental Protection : Valves help maintain safe operating conditions by regulating pressure, preventing backflow, and controlling potentially hazardous substances. They play a crucial role in environmental protection by preventing leaks and minimizing the release of pollutants.

d) System Efficiency : Valves contribute to system efficiency by controlling flow rates, optimizing energy consumption, and reducing pressure drops. They enable precise flow regulation, resulting in improved overall system performance.

e) Process Optimization : Valves facilitate process optimization by allowing control over process variables, such as flow rate, pressure, and temperature. This optimization leads to improved product quality, reduced waste, and increased productivity.

f) Reliability and Longevity : Well-designed and properly maintained valves ensure reliable operation and longevity of fluid control systems. Regular maintenance, including inspection, lubrication, and replacement of worn components, is crucial to prevent failures and ensure optimal performance.